The Critical Role of Optical Fibre Diameter Analyser in High-Speed Internet Infrastructure

The Critical Role of Optical Fibre Diameter Analyser in High-Speed Internet Infrastructure

Blog Article

Just How an Optical Fibre Diameter Analyser Improves High Quality Control in Fibre Production

The combination of an Optical Fibre Diameter Analyser right into Fibre production procedures stands for a substantial innovation in high quality control approaches. By providing real-time, precise dimensions of Fibre sizes, this modern technology addresses the crucial requirement for consistency in production criteria.

Importance of Fibre Diameter Dimension

Accurate dimension of Fibre Diameter is important in the area of optical Fibre technology, as it directly affects the performance and dependability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying ability, attenuation, and overall transmission efficiency. Precision in determining Fibre Diameter guarantees that the optical buildings are preserved within specified tolerances, which is vital for ideal signal honesty.

Variants in Fibre Diameter can cause increased losses as a result of scattering and modal dispersion, impacting the high quality of information transmission. In high-speed communication systems, such disparities can result in considerable deterioration of signal high quality, leading to information mistakes and minimized performance. Furthermore, constant Fibre Diameter is crucial for compatibility with ports and splicing innovations, which are essential parts of Fibre optic networks.

Quality assurance procedures in Fibre production greatly depend on precise Diameter measurements to make sure conformity with market criteria. By applying robust measurement techniques, suppliers can improve item dependability, lessen waste, and boost total system efficiency. Thus, the significance of Fibre Diameter dimension can not be overstated, as it acts as a cornerstone in the improvement of optical Fibre technology and its applications in modern interaction networks.

Just How the Analyser Works

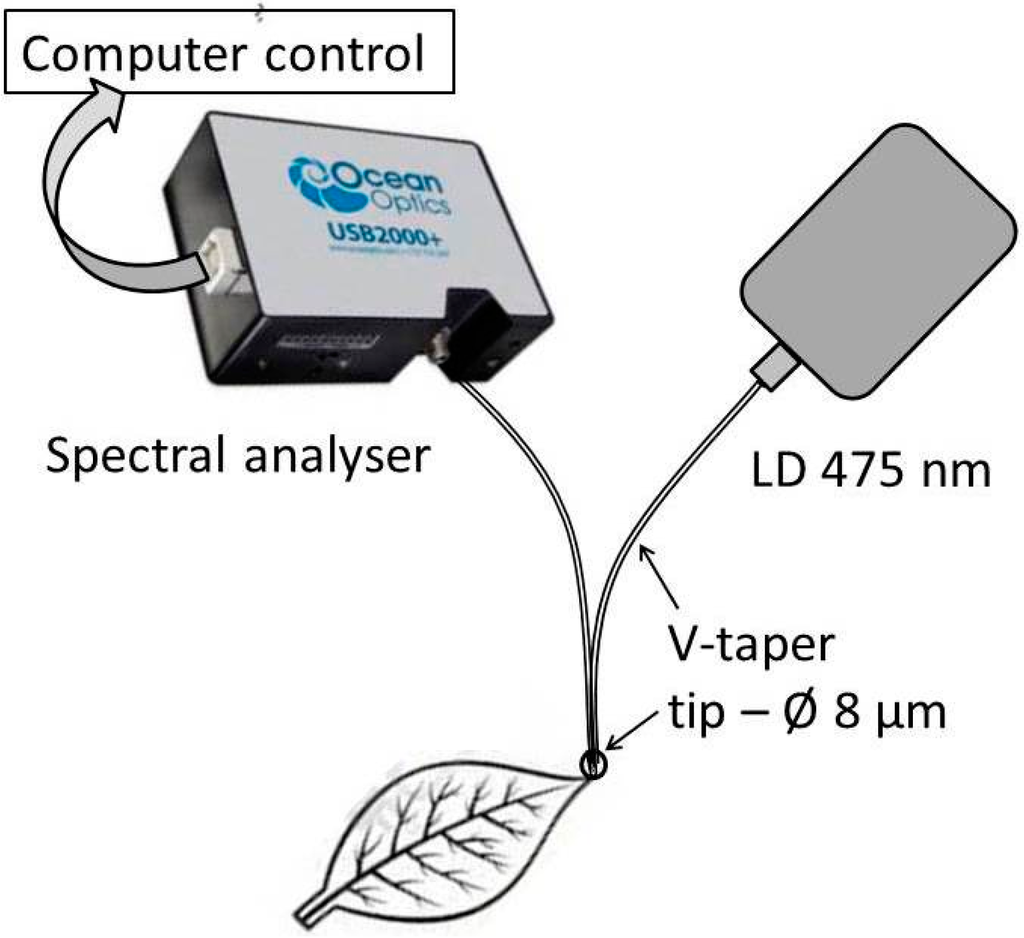

The efficient measurement of Fibre Diameter depends on advanced analytical techniques that ensure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a mix of laser technology and advanced picture handling algorithms to accurately analyze the Diameter of fibers as they are created

Initially, a laser beam is guided at the moving Fibre, producing a cross-sectional darkness. The analyser catches this shadow utilizing high-resolution electronic cameras placed purposefully along the manufacturing line. The captured images are after that processed in real-time to identify the Fibre's Diameter with outstanding accuracy.

The system utilizes advanced algorithms that represent various factors, consisting of variations in light intensity and ecological conditions, to boost dimension dependability. It can detect minute adjustments in Diameter, such as changes that may occur during the manufacturing procedure.

In addition, the analyser is qualified of dealing with multiple fibres simultaneously, enhancing throughput without endangering precision. By giving instantaneous responses on the Diameter, the Optical Fibre Diameter Analyser plays an important role in keeping stringent high quality control requirements, ensuring that the last item satisfies market specifications and client demands.

Advantages of Real-Time Surveillance

While typical methods of checking Fibre Diameter often include lengthy post-production checks, real-time tracking considerably enhances the effectiveness and top quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive approach allows manufacturers to recognize deviations in Fibre Diameter as they take place, rather than waiting till production is full to analyze top quality

By constantly determining the Diameter during production, producers can guarantee that the fibres fulfill rigid specs, resulting in decreased variability and improved consistency. Real-time tracking additionally enables prompt rehabilitative activities to be taken, decreasing waste and stopping faulty fibers from going into the supply chain.

Moreover, this technology helps with enhanced data collection and evaluation, giving understandings right into manufacturing trends and possible areas for enhancement. Such data-driven decision-making equips manufacturers to maximize processes and maintain high criteria of high quality control.

Furthermore, real-time surveillance fosters a society read what he said of continuous improvement within the production environment. Workers are a lot more engaged when they can why not try here see the influence of their operate in real-time, causing increased responsibility and a dedication to quality. In general, the application of real-time surveillance systems in optical Fibre production converts to superior product high quality and boosted customer complete satisfaction.

Influence on Manufacturing Performance

Implementing optical Fibre Diameter analysers considerably enhances manufacturing performance by simplifying the manufacturing procedure. These gadgets help with continuous surveillance of Fibre Diameter, permitting producers to find discrepancies in real-time. By determining disparities quickly, production lines can be readjusted promptly, minimizing downtime and lowering the chance of generating malfunctioning products.

Moreover, the combination of these analysers into the production workflow makes it possible for better source allowance. With precise Diameter measurements, drivers can enhance material usage, making certain that resources are not wasted on problematic fibers. This accuracy also contributes to less junk and revamp, inevitably reducing production prices.

The automation supplied by optical Fibre Diameter analysers minimizes reliance on hand-operated assessments, which are prone and usually time-consuming to human error. Therefore, employees can concentrate on more calculated tasks, enhancing overall efficiency.

Moreover, the data generated from these analysers can educate process renovations and help with much better decision-making. By evaluating patterns in Fibre Diameter variations, producers can carry out proactive procedures to boost manufacturing strategies and preserve consistent quality. In summary, optical Fibre Diameter analysers play an important function in enhancing production efficiency, leading to greater quality output and enhanced productivity.

Study and Success Stories

Throughout numerous markets, case research studies highlight the transformative effect of optical Fibre Diameter analysers on manufacturing processes. One popular example is a leading telecommunications company that faced challenges with inconsistent Fibre read more sizes, causing boosted being rejected prices. By integrating an optical Fibre Diameter analyser, the company achieved real-time surveillance of Fibre measurements, causing a 30% decrease in issues and significant price savings.

Moreover, a research study institution focusing on innovative materials used optical Fibre Diameter analysers to improve their speculative procedures. The analyser's capacity to supply detailed insights into Fibre consistency enabled the growth of innovative products with better performance qualities.

These success tales underscore the vital function of optical Fibre Diameter analysers in improving quality control, enhancing production efficiency, and driving technology throughout varied industries.

Verdict

In final thought, the Optical Fibre Diameter Analyser plays a critical function in enhancing top quality control within Fibre manufacturing. As shown with numerous instance research studies, the analyser shows necessary for achieving remarkable item quality in Fibre production.

The application of optical Fibre Diameter analysers enabled for rigid quality control, making sure that the produced fibres satisfied exacting sector requirements.In verdict, the Optical Fibre Diameter Analyser plays a crucial function in boosting top quality control within Fibre manufacturing.

Report this page